UA1665.RMAI

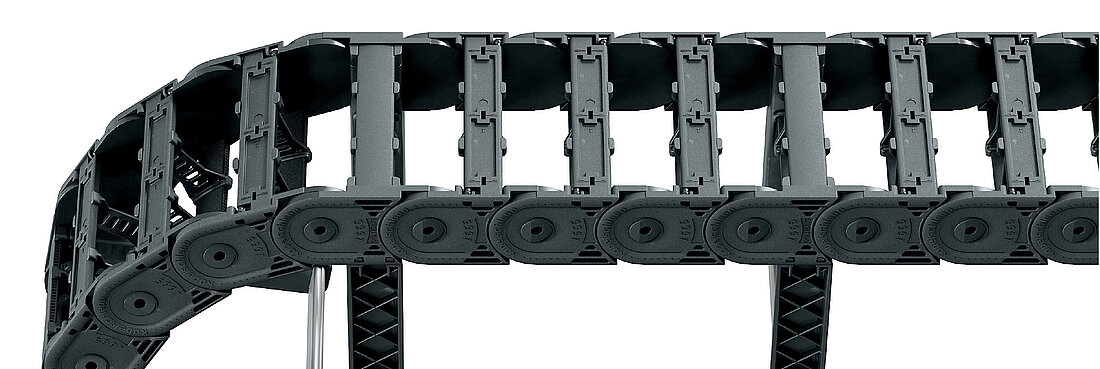

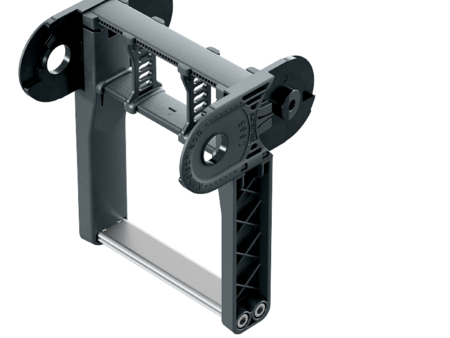

Aluminum stay RMAI – mounting frame stay

Properties

- Weight-optimized plastic frame with particularly high torsional rigidity.

- Plastic stays and aluminum profile bars with plastic mounting frame stays for guiding very large cable diameters.

- Inside: threaded joint easy to release.

Dimensions Dimensions

| Bi [mm] | |||

|---|---|---|---|

| 125 | 150 | 175 | 200 |

| Hi [mm] | |||

|---|---|---|---|

| 114 | 139 | 164 | 189 |

| KR [mm] | ||||||

|---|---|---|---|---|---|---|

| 75 | 100 | 120 | 140 | 200 | 250 | 300 |

Order example

RMAI – assembly to the inside:

standard pitch, mounting frame stay on every 4th stay, no screw fixing.

Gliding application is not possible when using assembly version RMAI.

Observe minimum KR:

Hi = 114 mm: KRmin = 200 mm

Hi = 139 mm: KRmin = 250 mm

Hi = 164 mm: KRmin = 300 mm

Hi = 189 mm: KRmin = 300 mm

Cross section mounting frame stay

To achieve a nearly square cross section in the mounting frame stay, we recommend the following combination of Bi and Hi:

| Bi [mm] | Hi [mm] | KRmin [mm] | Stays [mm] |

|---|---|---|---|

125 | 114 | 200 | 100 |

150 | 139 | 250 | 125 |

175 | 164 | 300 | 150 |

200 | 189 | 300 | 175 |

End connectors End connectors

| Bi [mm] | nz |

|---|---|

| 50 | 2 x 3 |

| 75 | 2 x 5 |

| 100 | 2 x 7 |

| 125 | 2 x 9 |

| 150 | 2 x 11 |

| 175 | 2 x 13 |

The end connectors are also available as an option with strain relief comb or with C-rail Art. no 3931 (1 on each side) for clamps. Please state when ordering.

Connection point

F – fixed point

M – driver

Connection type

U – Universal mounting bracket

Order example

We recommend the use of strain reliefs at the driver and fixed point.

| Bi [mm] | nz |

|---|---|

| 50 | 2 x 4 |

| 75 | 2 x 6 |

| 100 | 2 x 8 |

| 125 | 2 x 10 |

| 150 | 2 x 12 |

| 175 | 2 x 14 |

| 200 | 2 x 16 |

| 225 | 2 x 18 |

| 250 | 2 x 20 |

The end connectors are optionally also available without strain relief comb. Please state when ordering.

Connection point

F – fixed point

M – driver

Connection type

A – threaded joint outside (standard)

I – threaded joint inside

H – threaded joint, rotated 90° to the outside

K – threaded joint, rotated 90° to the inside