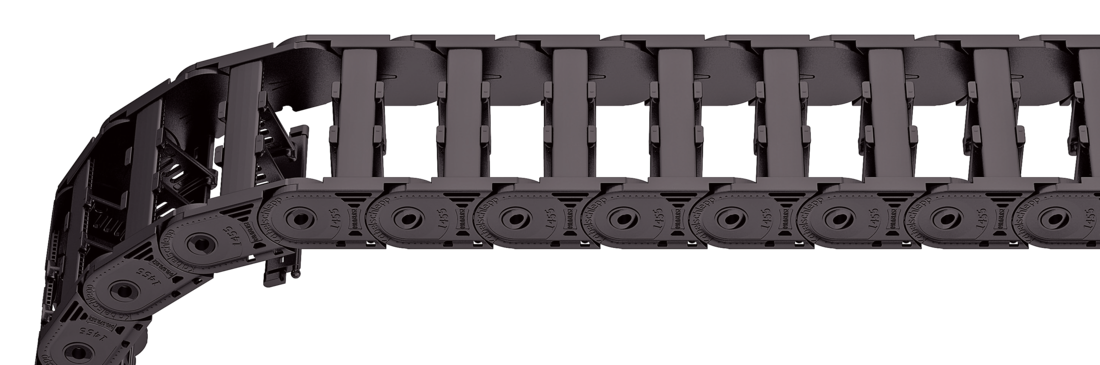

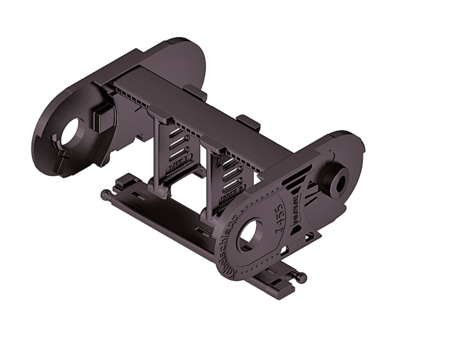

UA1455.040

Stay variant 040 – with inside opening and detachable stays

Properties

- Weight-optimised plastic frame with particularly high torsional rigidity.

- Swivable and detachable left or right in any position.

- Inside: openable and detachable.

Dimensions Dimensions

| Bi [mm] | |||||

|---|---|---|---|---|---|

| 25 | 38 | 58 | 78 | 103 | 130 |

| KR [mm] | ||||||

|---|---|---|---|---|---|---|

| 52 | 65 | 95 | 125 | 150 | 180 | 200 |

Order example

Inner Distribution Inner Distribution

Divider systems

The divider system is mounted on every 2nd chain link as a standard. As a standard, dividers or the complete divider system (dividers with height separations) are movable in the cross section (version A).

For applications with lateral acceleration and lying on the side, divider with arresting cams are available. The locking cams click into place in the locking grids in the stays (version B).

Divider system TS0

without height separation

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | ax grid [mm] | nT min |

|---|---|---|---|---|---|

| A | 3.5 | 7 | 5 | - | – |

| B | 4/5** | 7.5 | 5.5 | 2.5 | - |

** 4 mm for Bi 38 – 103; 5 mm for Bi 25, 130

Divider system TS1

with continuous height separation

| Vers. | aT min [mm] | aT max [mm] | ax min [mm] | ac min [mm] | ax grid [mm] | nT min |

|---|---|---|---|---|---|---|

| A | 3.5 | 20 | 7 | 5 | – | 2 |

| B | 4/5** | 20 | 7.5 | 5.5 | 2.5 | 2 |

** 4 mm for Bi 38 – 103; 5 mm for Bi 25, 130

Divider system TS3

with height separation consisting of plastic section subdivisions

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | nT min |

|---|---|---|---|---|

| A | 3.5 | 15 | 10 | 2 |

The dividers are fixed with the section subdivision. The entire divider system can be moved in the cross section.

ax (centre distance of dividers) [mm] | |||||||||

ac (usable width of inner chamber) [mm] | |||||||||

| 15 | 20 | 25 | 30 | 35 | 40 | 45 | 55 | 65 | 75 |

| 10 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 |

Order example

End connectors End connectors

| Bi [mm] | nz |

|---|---|

| 25 | 2 |

| 38 | 3 |

| 58 | 5 |

| 78 | 7 |

| 103 | 9 |

| 130 | 11 |

The end connectors are optionally also available with strain relief comb (1 on each side). Please state when ordering.

Connection point

F – fixed point

M – driver

Connection type

U – Universal mounting bracket

Order example

| Bi [mm] | nz |

|---|---|

| 25 | 2 x 2 |

| 38 | 2 x 3 |

| 58 | 2 x 4 |

| 78 | 2 x 6 |

| 103 | 2 x 8 |

| 130 | 2 x 10 |

The end connectors are optionally also available without strain relief comb (except Bi 25). Please state when ordering.

Connection point

F – fixed point

M – driver

Connection type

A – threaded joint outside (standard)

I – threaded joint inside

H – threaded joint, rotated 90° to the outside

K – threaded joint, rotated 90° to the inside

Order example

| Bi [mm] | nz |

|---|---|

| 25 | 2 x 2 |

| 38 | 2 x 3 |

| 58 | 2 x 4 |

| 78 | 2 x 6 |

| 103 | 2 x 8 |

| 130 | 2 x 10 |

The end connectors are optionally also available without strain relief comb (except Bi 25). Please state when ordering.

Connection point

F – fixed point

M – driver

Connection type

A – threaded joint outside (standard)

I – threaded joint inside

H – threaded joint, rotated 90° to the outside

K – threaded joint, rotated 90° to the inside