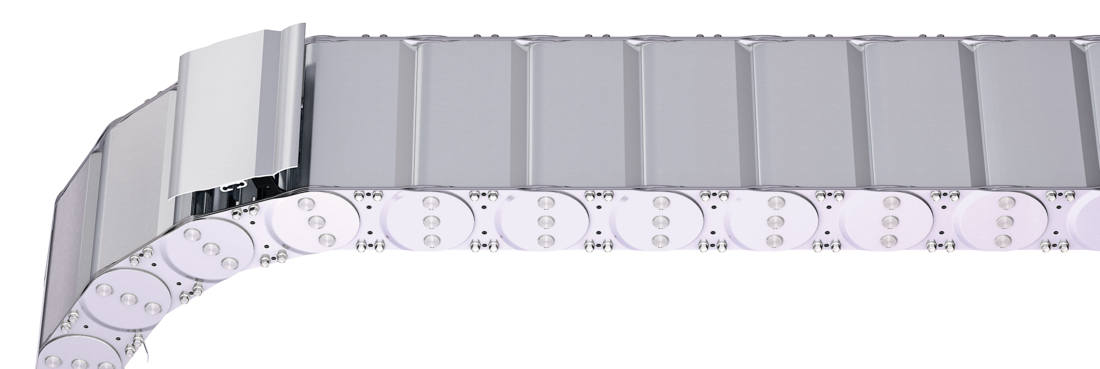

S/SX1250 Tubes RMD

Aluminum stay RMD – aluminum cover system

Properties

- Bolted aluminum covers for maximum stability.

- For applications generating chips or coarse contamination.

- Available customized in 1 mm grid.

- Inside/outside: Threaded joint easy to release.

Dimensions Dimensions

| KR [mm] * | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 200** | 220** | 260 | 300 | 340 | 380 | 420 | 460 | 500 | 540 | 600 | 1000 |

Order example

Inner Distribution Inner Distribution

Divider systems

As a standard, the divider system is mounted on every 2nd cover/chain link (HS).

As a standard, dividers or the complete divider system (dividers with height separations) are movable in the cross section (version A).

Divider system TS0

without height separation

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | nT min |

|---|---|---|---|---|

| A | 17.5 | 20 | 15 | – |

The dividers can be moved in the cross section.

Divider system TS1

with continuous height separation

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | nT min |

|---|---|---|---|---|

| A | 10 | 12 | 8 | 2 |

The dividers can be moved in the cross section.

Divider system TS2

with partial height separation

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | nT min |

|---|---|---|---|---|

| A | 11*/17** | 14*/21 | 8*/15 | 2 |

* For VR0

** For version with height separation to the end divider

With grid distribution (1 mm grid). The dividers are attached by the height separation, the grid can be moved in the cross section.

Sliding dividers are optionally available (thickness of divider = 4 mm).

Order example

End connectors End connectors

Connection point

F – fixed point

M – driver

Connection type

A – threaded joint outside (standard)

I – threaded joint inside

H – threaded joint, rotated 90° to the outside

K – threaded joint, rotated 90° to the inside

Connection surface

I – connection surface inside (standard)

A – connecting surface outside

Order example

We recommend the use of strain reliefs at the driver and fixed point.