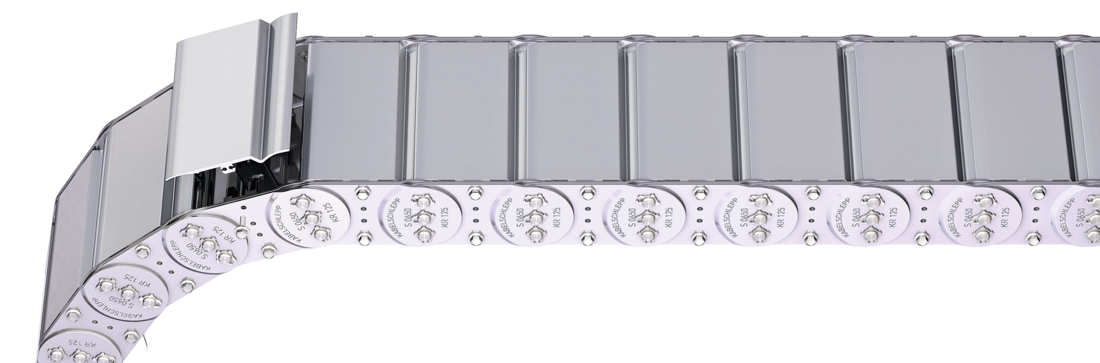

S/SX0650 Tubes RMD

Aluminum stay RMD – aluminum cover system

Properties

- Bolted aluminum covers for maximum stability.

- For applications generating chips or coarse contamination.

- Available customized in 1 mm grid.

- Inside/outside: Threaded joint easy to release.

Dimensions Dimensions

| KR [mm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 115 | 125 | 135 | 145 | 155 | 175 | 200 | 250 | 300 | 400 |

Order example

Inner Distribution Inner Distribution

Divider systems

As a standard, the divider system is mounted on every 2nd cover/chain link (HS).

As a standard, dividers or the complete divider system (dividers with height separations) are movable in the cross section (version A).

Divider system TS0

without height separation

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | nT min |

|---|---|---|---|---|

| A | 11.5 | 13 | 10 | – |

The dividers can be moved in the cross section.

Divider system TS1

with continuous height separation

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | nT min |

|---|---|---|---|---|

| A | 11.5 | 13 | 10 | 2 |

The dividers can be moved in the cross section.

Order example

Please state the designation of the divider system (TS0, TS1 …), version and number of dividers per cross section [nT].

If using divider systems with height separation (TS1) please also state the positions [e.g. VD1] viewed from the left driver belt. You are welcome to add a sketch to your order.

The end dividers are part of the divider system and don‘t have to be ordered separately.

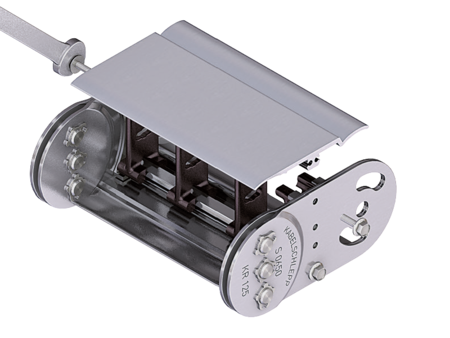

End connectors End connectors

Connection point

F – fixed point

M – driver

Connection type

A – threaded joint outside (standard)

I – threaded joint inside

H – threaded joint, rotated 90° to the outside

K – threaded joint, rotated 90° to the inside

Connection surface

A – connection surface inside (standard)

I – connection surface outside

Order example

We recommend the use of strain reliefs at the driver and fixed point.