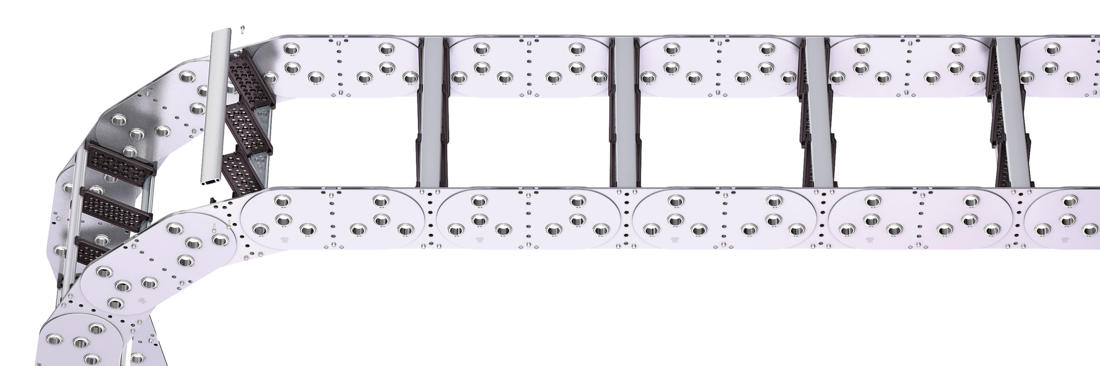

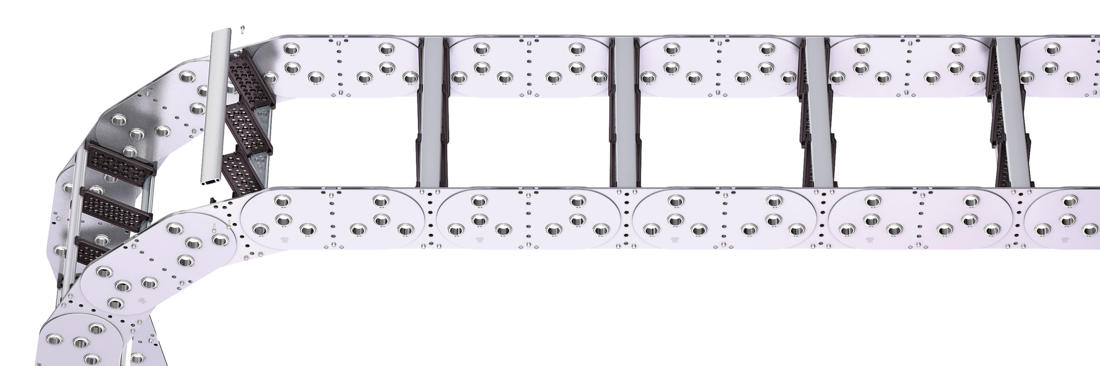

S/SX2500 RM

S/SX2500 RM

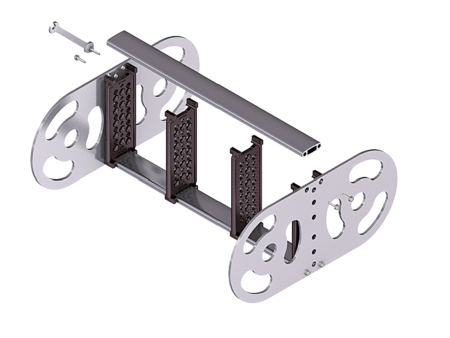

Aluminum stay RM – frame stay, solid

Properties

- Aluminum profile bars for heavy loads and maximum cable carrier widths. Double threaded joint on both sides “Heavy Duty”.

- Available customized in 1 mm grid.

- Inside/outside: Threaded joint easy to release.

Dimensions Dimensions

Calculating the cable carrier length

Cable carrier length Lk: Lk ≈ LS/2 + LB

Cable carrier length Lk rounded to pitch t for odd number of chain links

* in 1 mm width sections

| KR [mm] | |||||||

|---|---|---|---|---|---|---|---|

| 365 | 445 | 600 | 760 | 920 | 1,075 | 1,235 | 1,395 |

Order example

S2500

Type

•

806

BSt [mm]

•

RM

Stay variant

•

760

KR [mm]

•

St

Material

-

9250

Lk [mm]

HS

Stay arrangement

Inner Distribution Inner Distribution

Divider systems

As a standard, the divider system is mounted on each crossbar – for stay mounting on every 2nd chain link (HS).

As a standard, dividers and the complete divider system (dividers with height separations) can be moved in the cross section (version A).

Divider system TS0

without height separation

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | nT min |

|---|---|---|---|---|

| A | 19 | 25 | 13 | – |

The dividers can be moved in the cross section.

Divider system TS1

with continuous height separation

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | nT min |

|---|---|---|---|---|

| A | 19 | 13 | 25 | 2 |

The dividers can be moved in the cross section.

Divider system TS2

with partial height separation

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | nT min |

|---|---|---|---|---|

| A | 40 | 46 | 34 | 2 |

Standard height separation with tube Ø 16 mm.

The dividers can be moved in the cross section.

Order example

TS2

Divider system

•

A

Version

•

2

nT

•

K1

•

K3

Chamber

•

34

•

38

ax

-

VR1

-

VR3

Height separation

End connectors End connectors

Connection point

F – fixed point

M – driver

Connection type

A – threaded joint outside (standard)

I – threaded joint inside

Order example

Steel

Steel

End connector

•

F

•

M

Connection point

A

A

Connection type

We recommend the use of strain reliefs at the driver and fixed point.