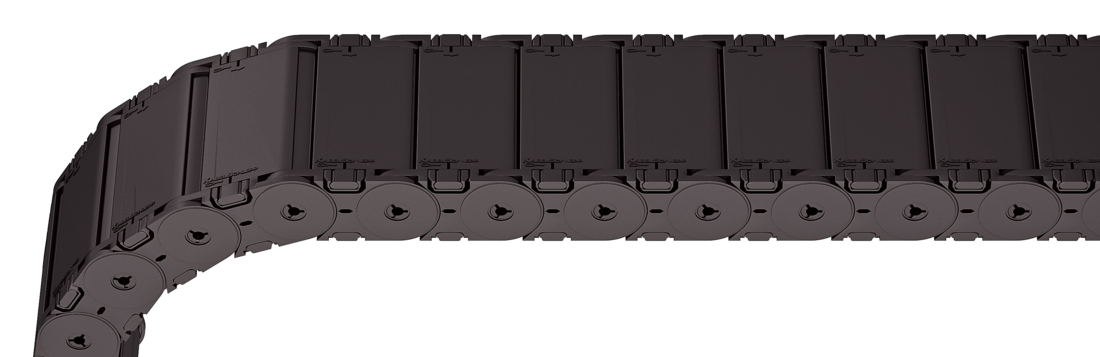

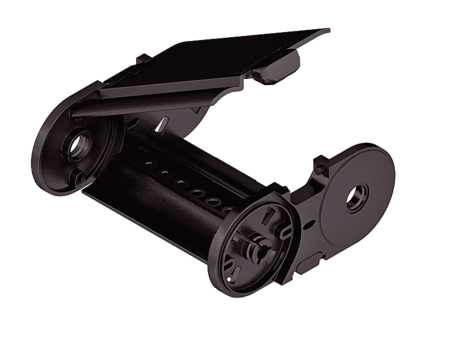

MT0475 RDD 02

Plastic cover RDD 02 – cover with hinge in the outer radius

Properties

- Plastic cover system with hinge for light and medium loads. Assembly without screws.

- Available customized in 8 mm sections.

- Outside: swivable to both sides.

- Inside: release by turning 90°.

Dimensions Dimensions

| Bi [mm] * | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 24 | 32 | 40 | 48 | 56 | 64 | 72 | 80 | 88 | 96 |

| 104 | 112 | 120 | 128 | 136 | 144 | 152 | 160 | 168 | 176 |

| 184 | 192 | 200 | 208 | 216 | 224 | 232 | 240 | 248 | 256 |

| 264 | 272 | 280 | |||||||

| KR [mm] | ||||||

|---|---|---|---|---|---|---|

| 75 | 100 | 130 | 160 | 200 | 250 | 300 |

Order example

Inner Distribution Inner Distribution

Divider systems

As a standard, the divider system is assembled at every 2nd chain link.

For applications with lateral acceleration and laying on the side, the dividers or the complete divider system (dividers with height separations) are fixed in the cross section. The arresting cams click into place in the locking grids in the crossbars (version B).

Divider system TS0

without height separation

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | ax grid [mm] | nT min |

|---|---|---|---|---|---|

| B | 6 | 7.8 | 5 | 8 | – |

Divider system TS1

with continuous height separation

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | ax grid [mm] | nT min |

|---|---|---|---|---|---|

| B | 6 | 7.8 | 5 | 8 | 2 |

The dividers are fixed in the cross section (version B).

Divider system TS2

with partial height separation

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | ax grid [mm] | nT min |

|---|---|---|---|---|---|

| B | 12 | 8*/24 | 5.2*/21.2 | 8 | 2 |

* for VR0

With grid distribution (8 mm grid). The dividers are fixed by the height separation, the grid is fixed in the cross section (version B).

Order example

End connectors End connectors

| Bi [mm] | x [mm] | nz |

|---|---|---|

| 40 | 17.5 | 3 |

| 56 | 21.5 | 4 |

| 80 | 17.5 | 6 |

| 104 | 19.0 | 8 |

| 128 | 19.5 | 9 |

| 152 | 17.5 | 11 |

| 192 | 18.5 | 14 |

Other widths only available without strain relief.

Connection point

F – fixed point

M – driver

Connection type

A – threaded joint outside (standard)

I – threaded joint inside

Connection surface

I – connection surface inside

Order example

Connection point

F – fixed point

M – driver

Connection type

A – threaded joint outside (standard)

I – threaded joint inside

F – flange connection

Connection surface

A – connection surface outside

I – connection surface inside

Order example

We recommend the use of strain reliefs at the driver and fixed point.