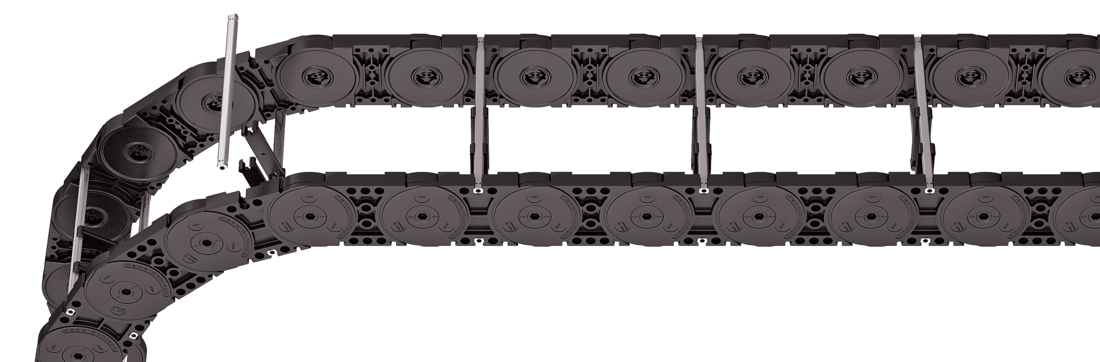

MC1250 RS

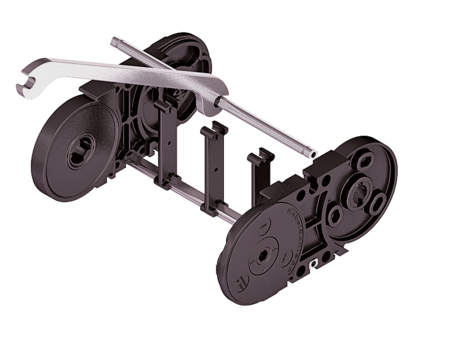

Aluminum stay RS – frame stay narrow

Properties

- Extremely quick to open and close

- Aluminum profile bars for light to medium loads. Assembly without screws.

- Available customized in 1 mm grid.

- Outside/inside: release by turning by 90°.

Dimensions Dimensions

| KR [mm] | ||||||

|---|---|---|---|---|---|---|

| 180 | 220 | 260 | 300 | 340 | 380 | 500 |

Order example

Inner Distribution Inner Distribution

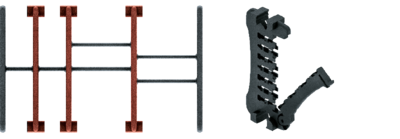

Divider systems

Divider systems

As a standard, the divider system is mounted on each crossbar – for stay mounting on every 2nd chain link (HS). As a standard, dividers and the complete divider system (dividers with height separations) can be moved in the cross section (version A).

For applications with lateral acceleration and rotated by 90°, the dividers can be attached by simply clipping on a socket (available as an accessory). The bushing additionally serves as a spacer between the dividers and is available in 1 mm sections between 3 – 50 mm (version B).

Divider system TS0

without height separation

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | nT min |

|---|---|---|---|---|

| A | 7.5 | 15 | 10 | 2 |

The dividers can be moved in the cross section.

Divider system TS1

with continuous height separation

| Vers. | aT min [mm] | aT max [mm] | ax min [mm] | ac min [mm] | nT min |

|---|---|---|---|---|---|

| A | 7.5 | 25 | 15 | 10 | 2 |

The dividers can be moved in the cross section.

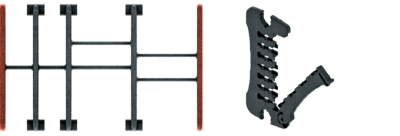

Divider system TS3

with height separation consisting of plastic partitions

As a standard, the divider version A is used for vertical partitioning within the cable carrier. The complete divider system can be moved within the cross section.

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | nT min |

|---|---|---|---|---|

| A | 6/2* | 14 | 10 | 2 |

* for End divider

The dividers are fixed with the partitions. The entire divider system can be moved in the cross section.

ax (center distance of dividers) [mm] | |||||||||||

ac (nominal width of inner chamber) [mm] | |||||||||||

| 14 | 16 | 19 | 23 | 24 | 28 | 29 | 32 | 33 | 34 | 38 | 39 |

| 10 | 12 | 15 | 19 | 20 | 24 | 25 | 28 | 29 | 30 | 34 | 35 |

| 43 | 44 | 48 | 49 | 54 | 58 | 59 | 64 | 68 | 69 | 74 | 78 |

| 39 | 40 | 44 | 45 | 50 | 54 | 55 | 60 | 64 | 65 | 70 | 74 |

| 79 | 80 | 84 | 88 | 89 | 94 | 96 | 99 | 112 | |||

| 75 | 76 | 80 | 84 | 85 | 90 | 92 | 95 | 108 | |||

When using partitions with ax > 49 mm we recommended an additional preferential central support.

Order example

Please state the designation of the divider system (TS0, TS1,...), version and number of dividers per cross section [nT ]. In addition, please also enter the chambers [K] from left to right, as well as the assembly distances [aT/ax] (as seen from the driver).

If using divider systems with height separation (TS1 – TS3), please also state the positions [e.g. VD23] viewed from the left driver belt. You are welcome to add a sketch to your order.

End connectors End connectors

Connection point

F – fixed point

M – driver

Connection type

U – universal mounting bracket

Order example

We recommend the use of strain reliefs at the driver and fixed point.

Connection point

F – fixed point

M – driver

Connection type

A – threaded joint outside (standard)

I – threaded joint inside

F – flange connection

Connection surface

I – connection surface inside

A – connection surface outside

Order example

We recommend the use of strain reliefs at the driver and fixed point.