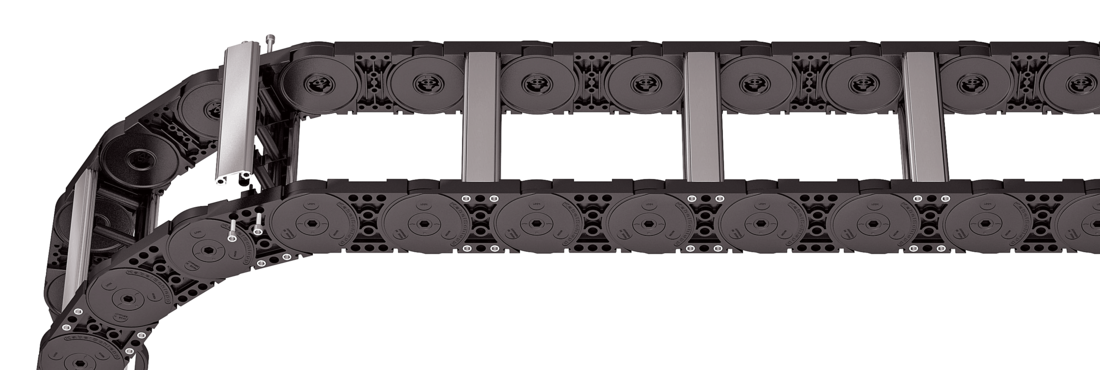

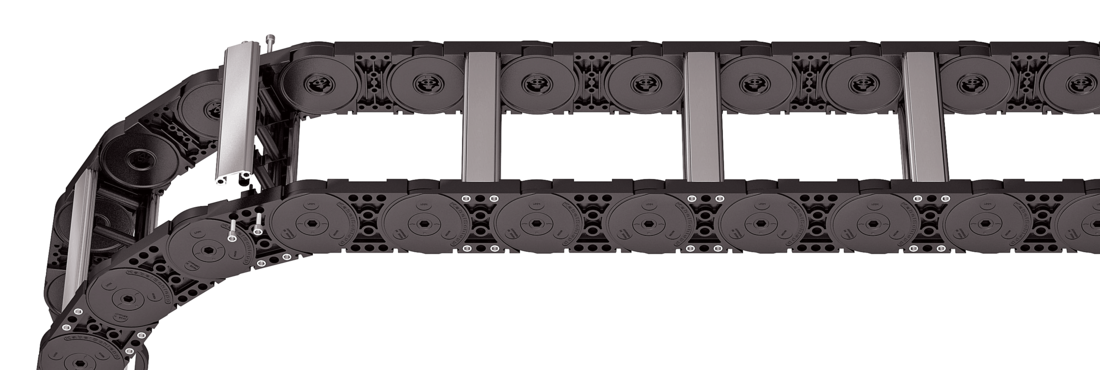

MC1250 RMR

MC1250 RMR

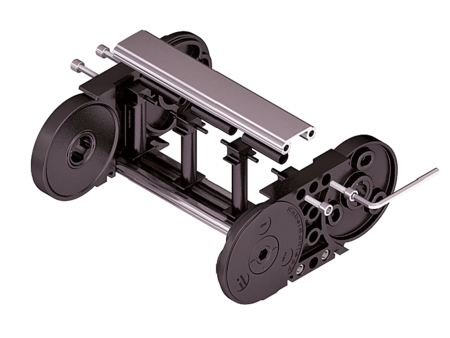

Aluminum stay RMR – Frame rolling stay

Properties

- Aluminum profile bars with rotating plastic rolling stay for highest requirements with gentle cable guiding. Double threaded joint on both sides.

- Available customized in 1 mm grid.

- Inside/outside: Threaded joint easy to release.

Dimensions Dimensions

Calculating the cable carrier length

Cable carrier length Lk: Lk ≈ LS/2 + LB

Cable carrier length Lk rounded to pitch t

* in 1 mm width sections

| KR [mm] | ||||||

|---|---|---|---|---|---|---|

| 180 | 220 | 260 | 300 | 340 | 380 | 500 |

Order example

MC1250

Type

•

400

Bi [mm]

•

RMR

Stay variant

•

300

KR [mm]

-

4250

Lk [mm]

HS

Stay arrangement

End connectors End connectors

Connection point

F – fixed point

M – driver

Connection type

U – universal mounting bracket

Order example

UMB

UMB

End connector

•

F

•

M

Connection point

U

U

Connection type

We recommend the use of strain reliefs at the driver and fixed point.

Connection point

F – fixed point

M – driver

Connection type

A – threaded joint outside (standard)

I – threaded joint inside

F – flange connection

Connection surface

I – connection surface inside

A – connection surface outside

Order example

Plastic/steel

Plastic/steel

End connector

F

M

Connection point

A

A

Connection type

A

I

Connection surface

We recommend the use of strain reliefs at the driver and fixed point.