LS/LSX1050 RR

LS/LSX1050 RR

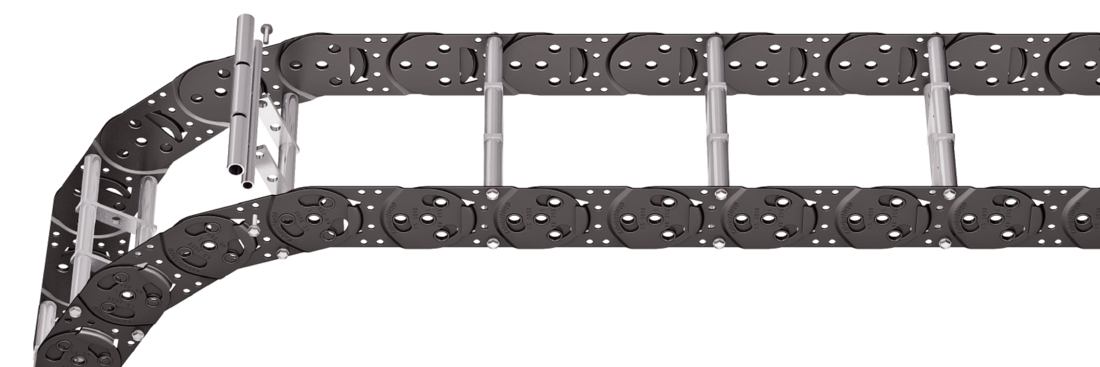

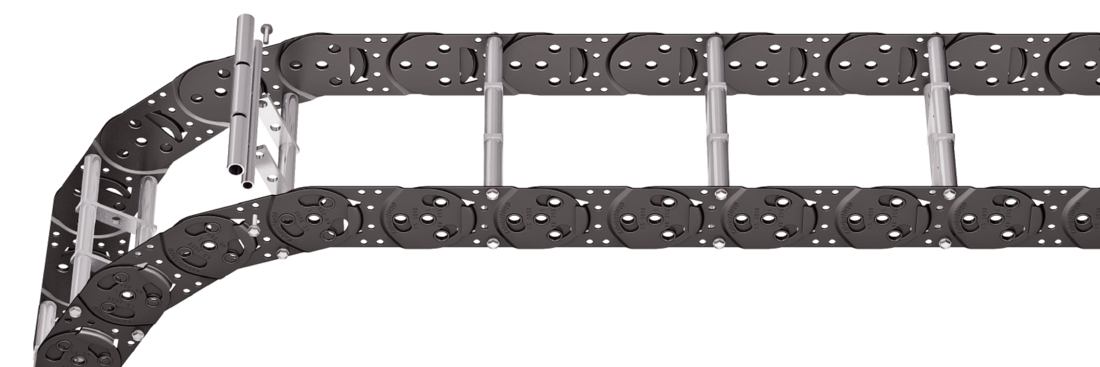

Tube stay RR – frame stay, tube version

Properties

- Steel rolling stays with gentle cable support and steel dividers. Ideal for using media hoses with soft sheathing. Easy screw connection.

- Available customized in 1 mm width sections.

- Inside/outside: Screw connection detachable

- Option: Divider systems made from steel and stainless steel ER 1, ER 1S.

Dimensions Dimensions

Calculating the cable carrier length

Cable carrier length Lk: Lk ≈ LS/2 + LB

Cable carrier length Lk rounded to pitch t

* in 1 mm width sections

| KR [mm] | ||||||||

|---|---|---|---|---|---|---|---|---|

| 105 | 125 | 155 | 195 | 260 | 295 | 325 | 365 | 430 |

Order example

LS1050

Type

•

180

BSt [mm]

•

RR

Stay variant

•

125

KR [mm]

•

Sb

Material

-

2415

Lk [mm]

HS

Stay arrangement

Inner Distribution Inner Distribution

Divider systems

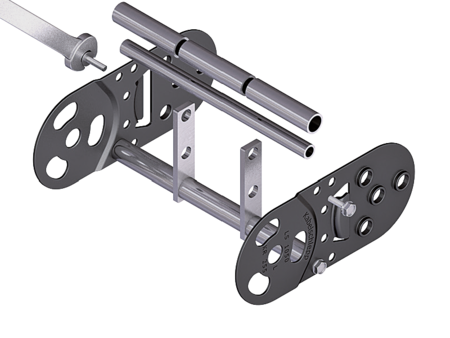

As a standard, the divider system is mounted on each crossbar – for stay mounting on every 2nd chain link (HS).

The dividers are fixed through the tubes. The tube additionally serves as a spacer between the dividers (version B).

Divider system TS0

without height separation

| Vers. | aT min [mm] | ax min [mm] | ac min [mm] | nT min |

|---|---|---|---|---|

| B | 20 | 20 | 16 | – |

Divider system TS1

with continuous height separation

| Vers. | aT min [mm] | aT max [mm] | ax min [mm] | ac min [mm] | nT min |

|---|---|---|---|---|---|

| B | 20 | 25 | 20 | 16 | 2 |

Order example

TS1

Divider system

•

B

Version

•

3

nT

•

K1

•

K4

Chamber

•

34

•

38

ax

-

VD0

-

VD0

Height separation

Please state the designation of the divider system (TS0, TS1 …), version and number of dividers per cross section [nT]. In addition, please also enter the chambers [K] from left to right, as well as the assembly distances [aT/ax] (as seen from the driver).

End connectors End connectors

Connection point

F – fixed point

M – driver

Connection type

A – threaded joint outside (standard)

I – threaded joint inside

Connection surface

A – connecting surface outside

I – connecting surface inside

Order example

Steel

Steel

End connector

•

F

•

M

Connection point

A

A

Connection type

I

I

Connection surface

We recommend the use of strain reliefs before driver and fixed point.