K0650

K0650

Pitch

65 mm

65 mm

Inner heights

36 - 42 mm

36 - 42 mm

Inner widths

68 - 600 mm

68 - 600 mm

Bending radii

75 - 300 mm

75 - 300 mm

Stay Variants

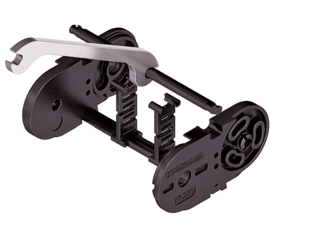

KC0650 RS

more details

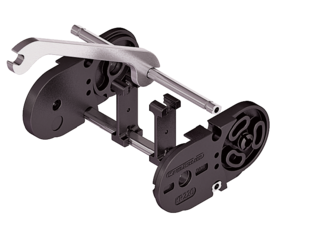

KC0650 LG

more details

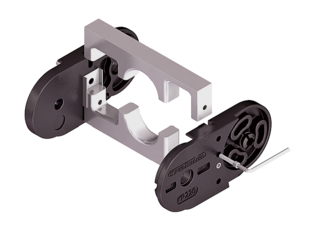

KC0650 RMAI

more details

KC0650 RMAO

more details

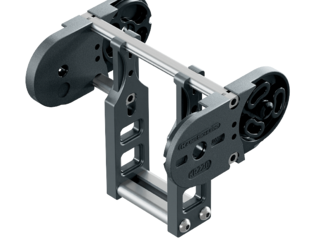

KE0650 RE

more details

Stay Variants

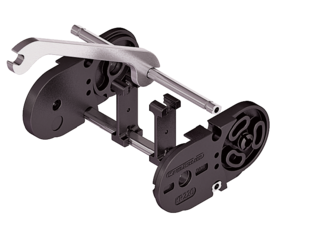

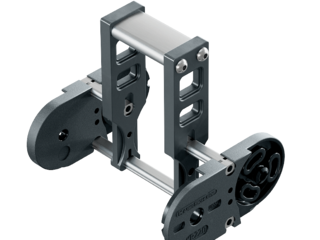

KC0650 RS

Frame stay, narrow "The standard"

- Aluminum profile bars for light to medium loads. Assembly without screws.

- Outside/inside: to open by rotating 90°.

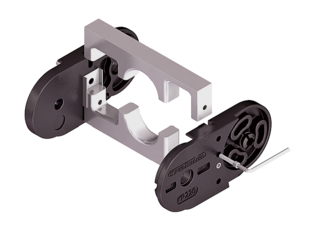

KC0650 LG

Hole stay, split version

- Optimum cable routing in the neutral bending line. Split version for easy cable routing. Stays also available unsplit.

- Outside/inside: Screw-fixing easy to release.

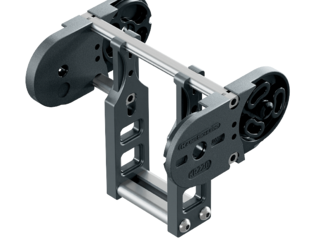

KC0650 RMAI

Mounting frame stay

- Aluminum profile bars with plastic mounting frame stays for guiding very large cable diameters.

- Inside: Screw-fixing easy to release.

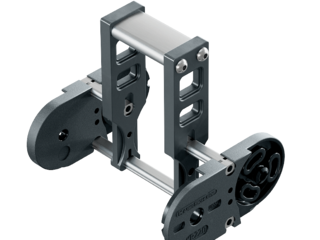

KC0650 RMAO

Mounting frame stay

- Aluminum profile bars with plastic mounting frame stays for guiding very large cable diameters.

- Outside: Screw-fixing easy to release.

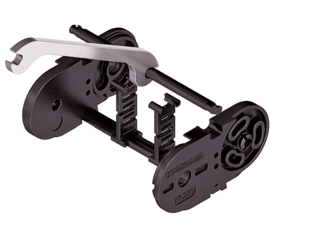

KE0650 RE

Frame screw-in stay

- Plastic profile bars for light to medium loads. Assembly without screws.

- Outside/inside: to open by rotating 90°.

Installation dimensions

Installation dimensions

UNSUPPORTED ARRANGEMENT

| KR [mm] | H [mm] | Hz [mm] | LB [mm] | UB [mm] |

|---|---|---|---|---|

| 75 | 205 | 245 | 366 | 168 |

| 115 | 285 | 325 | 492 | 208 |

| 145 | 345 | 385 | 586 | 238 |

| 175 | 405 | 445 | 680 | 268 |

| 220 | 495 | 535 | 822 | 313 |

| 300 | 655 | 695 | 1073 | 393 |

LOAD DIAGRAM FOR UNSUPPORTED LENGTH

depending on the additional load.

Sagging of the cable carrier is technically permitted for extended travel lengths, depending on the specific application.

Intrinsic cable carrier weight qk = 2.5 kg/m. For other inner widths, the maximum additional load changes.

GLIDING ARRANGEMENT

If the cable carrier is positioned so it is rotated by 90° (gliding on the outside of the side band), slide discs snapped onto the side optimize the friction and wear situation.