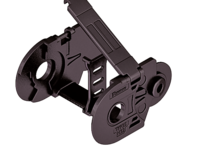

TKP35.030

Stay variant 030 – with outside opening and detachable crossbars

Properties

- Weight-optimised plastic frame with particularly high torsional rigidity.

- Can be opened at any position on both sides.

- Outside: opening and detachable crossbars.

Dimensions

The maximum cable diameter strongly depends on the bending radius and the desired cable type.

Please contact us.

Calculating the cable carrier length

hi

[mm]

|

hG

[mm]

|

Bi

[mm]

|

Bk

[mm]

|

qk

[kg/m]

| |||

|---|---|---|---|---|---|---|---|

| 32 | 40 | 16 | 25 | 38 | 50 | Bi + 12* | 0.50 – 0.80 |

KR

[mm]

| ||||

|---|---|---|---|---|

| 48 | 60 | 75 | 100 | 125 |

* For Bi 16 = Bi + 10

Order example

TKP35

030

50

100

700

VS

Inner distribution

The divider system is mounted on every 2nd chain link as a standard. As a standard, dividers or the complete divider system (dividers with height separations) are movable in the cross section (Version A).

For applications with lateral accelerations and applications with the cable carrier rotated by 90°, the dividers can easily be fixed on the stay through rotation. The arresting cams snap into the catch profiles in the covers (version B).

| Vers. |

aT min

[mm]

|

ax min

[mm]

|

ac min

[mm]

|

ax grid

[mm]

|

nT min |

|---|---|---|---|---|---|

| A | 3 | 6 | 4 | – | – |

| B | 4,5* / 5 | 6 | 4 | 2 | – |

* only Bi 25

| Vers. |

aT min

[mm]

|

ax min

[mm]

|

ac min

[mm]

|

ax grid

[mm]

|

nT min |

|---|---|---|---|---|---|

| A | 3 | 6 | 4 | – | 2 |

| B | 4,5* / 5 | 6 | 4 | 2 | 2 |

* only Bi 25

The dividers can be moved in the cross section.

Order example

TS1

A

3

VD1

VD3

Please state the designation of the divider system (TS0, TS1 …), version and number of dividers per cross section [nT].

If using divider systems with height separation (TS1), please also state the positions [e.g. VD1] viewed from the left driver belt. You are welcome to add a sketch to your order.

End connectors

Single-part end connectors – plastic (suitable for Bi 16)

The plastic end connectors can be connected from above or below. The connection type can be changed by altering the position of the end connector.

F – fixed point

M – driver

A – threaded joint outside (standard)

I – threaded joint inside

Single-part end connectors – plastic (suitable for Bi 25 – 50)

The plastic end connectors can be connected from above or below. The connection type can be changed by altering the position of the end connector.

The end connectors are optionally also available without strain relief comb.

Bi [mm] |

BEF [mm] | nz |

|---|---|---|

25 | 37 | 2 |

38 | 50 | 4 |

50 | 62 | 6 |

F – fixed point

M – driver

A – threaded joint outside (standard)

I – threaded joint inside

Order example

End connector

F

A

End connector

M

A

End connector

End connector

F

M

A

A