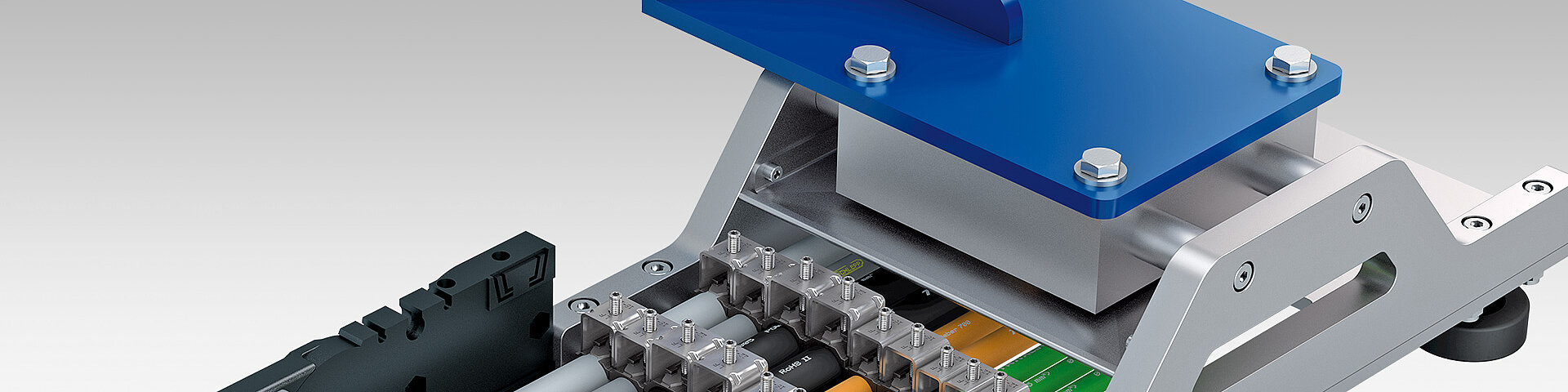

Floating Moving Device (TKFMD)

Optimum transfer of cables

Floating Moving Device (TKFMD) – To compensate for lateral offset in cable carriers

A flexible driver connection is required to ensure guiding of the cable carrier without transverse forces in applications with increased lateral offset. The connection has to ensure a relative movement between the connection of the cable carrier system and the system driver.

Features

- Tolerance compensation:

- Horizontal: max. +/- 30 mm,

vertical: max. +/- 20 mm - Inaccuracies in channel alignment/manufacturing/assembly are compensated

- Horizontal: max. +/- 30 mm,

- Continued cable routing

No threading or passing through of the tail lengths required - Wear

- Wear reduced to a minimum

- Roller-guided system in connection with all Tsubaki Kabelschlepp guide channels

- Material

Stainless steel/aluminum, or painted to customer specifications - Easy installation

The cable carrier system has two defined mounting assemblies for easy installation of cables and hoses - Cable routing

The protected continued cable routing in the Floating Moving Device corresponds to the inner height of the cable carrier - Strain relief

Easy access and assembly with LineFix clamps for strairelief - Standard connection dimensions

For horizontal and vertical connection including GO module (friction-optimized for low wear)

Relevant factors

- Guiding without transverse forces:

- protects the cable carrier

- minimizes costs through reduced downtimes

- reduces defects/malfunctions/damage

- The compensation of the parallel error between the system and the cable carrier is ensured

- Easy maintenance/disassembly, if necessary

- Easy retrofitting on an opposite-arrangement system

- Easy connection options

- System reliability and availability

Suitable for:

| Type | Inner width Bi [mm] |

|---|---|

M0950 | 130 – 500 |

M1250 | 150 – 800 |

M1300 | 140 – 500 |

* Additional inner widths on request.

Single-sided arrangement

Opposite arrangement